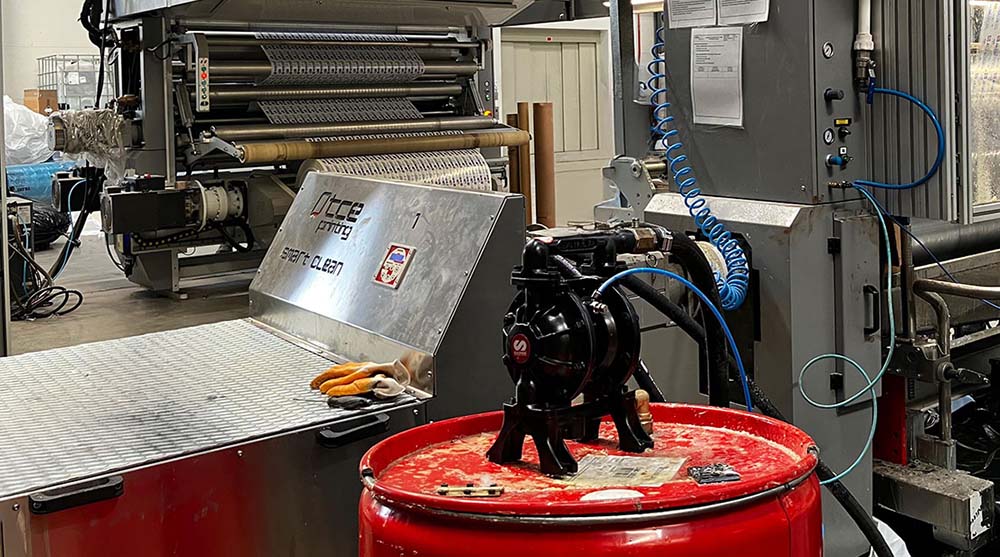

Diaphragm pumps for the printing and packaging Industry

In the printing and packaging industry, fluid handling plays a critical role in maintaining quality and efficiency. Diaphragm pumps have become the preferred solution for transferring inks, solvents, and coatings thanks to their reliable performance, chemical resistance and ability to handle a wide range of viscosities.

Whether used in flexographic, gravure, or packaging printing, these pumps help ensure smooth, clog-free operation while preserving the integrity of printing materials.

Common challenges in printing applications

Ink and coating transfer presents several challenges:

• Inconsistent flow and pulsation

• Clogging due to viscosity variation

• Ink foaming and separation

• Wear from aggressive chemicals

These issues can lead to waste, downtime, and reduced print quality. The right pump technology helps to eliminate these problems and keeps operations running smoothly.

• Inconsistent flow and pulsation

• Clogging due to viscosity variation

• Ink foaming and separation

• Wear from aggressive chemicals

These issues can lead to waste, downtime, and reduced print quality. The right pump technology helps to eliminate these problems and keeps operations running smoothly.

Why choose an air-operated double diaphragm pump (AODD)?

AODD pumps are engineered for demanding printing environments. Their self-priming capability and low shear handling make them ideal for sensitive inks and coatings, while their corrosion-resistant materials support long service life and reduced maintenance needs.

Key Benefits:

• Clog-resistant design for various viscosities

• Low maintenance and minimal wear parts

• Compatible with water-based, solvent-based, and UV-curable inks

• Dry-run capable and self-priming

These features make AODD pumps a smart investment for print shops and packaging lines alike.

Key Benefits:

• Clog-resistant design for various viscosities

• Low maintenance and minimal wear parts

• Compatible with water-based, solvent-based, and UV-curable inks

• Dry-run capable and self-priming

These features make AODD pumps a smart investment for print shops and packaging lines alike.

Comparison: diaphragm pumps vs. piston and peristaltic pumps

While piston and peristaltic pumps are also used in industrial settings, they come with limitations:

• Piston pumps offer precise volume control but require more frequent maintenance due to mechanical complexity.

• Peristaltic pumps minimize contamination but suffer from high wear rates and limited chemical compatibility.

In contrast, pneumatic diaphragm pumps deliver the best combination of durability, versatility, and operational efficiency —making them the top choice for the printing sector.

• Piston pumps offer precise volume control but require more frequent maintenance due to mechanical complexity.

• Peristaltic pumps minimize contamination but suffer from high wear rates and limited chemical compatibility.

In contrast, pneumatic diaphragm pumps deliver the best combination of durability, versatility, and operational efficiency —making them the top choice for the printing sector.

Selecting the right pump size

Choosing the correct pump size is essential for optimizing performance:

• 1/2" and 1" diaphragm pumps: Ideal for small to mid-sized applications with moderate flow requirements.

• 1.5" diaphragm pumps: Designed for high-volume operations and large-scale packaging environments.

Not sure what size you need? Our experts can help you assess your system and recommend the best fit.

• 1/2" and 1" diaphragm pumps: Ideal for small to mid-sized applications with moderate flow requirements.

• 1.5" diaphragm pumps: Designed for high-volume operations and large-scale packaging environments.

Not sure what size you need? Our experts can help you assess your system and recommend the best fit.

What to consider when choosing a printing pump

When selecting a pump for printing applications, consider:

• Fluid Compatibility: Can the pump handle your ink or coating formulation?

• Operational Downtime: Will the pump minimize maintenance needs and avoid unnecessary stops?

• Long-Term Cost: Does the pump offer durability and low service costs over time?

With the right setup, you can maximize uptime, maintain print consistency, and improve overall efficiency.

• Fluid Compatibility: Can the pump handle your ink or coating formulation?

• Operational Downtime: Will the pump minimize maintenance needs and avoid unnecessary stops?

• Long-Term Cost: Does the pump offer durability and low service costs over time?

With the right setup, you can maximize uptime, maintain print consistency, and improve overall efficiency.

Trusted performance for the packaging industry

AODD pumps have proven themselves across countless printing operations in the packaging sector. Their robust design and flexible compatibility often makes them the industry’s go-to solution for reliable ink and coating transfer.

Upgrade your printing system with diaphragm pump technology built for performance, efficiency, and longevity.

Upgrade your printing system with diaphragm pump technology built for performance, efficiency, and longevity.