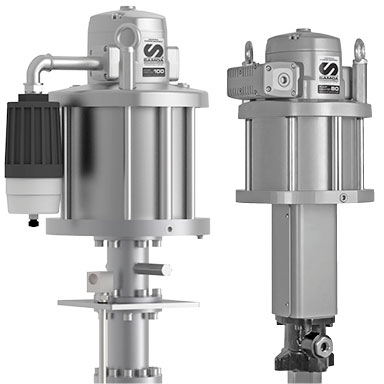

Compressed air-driven piston pumps

Piston Pumps

Air-operated pumps for industrial applications are suited for long pipelines, high flow rates, and numerous simultaneous outlets. Piston pumps are used in a variety of fluid handling applications. The majority of these can be categorized into four different types:

• Transfer

Simple transfer involves moving a fluid with low to medium viscosity from one location to another. Double-Ball and Power-Piston pumps are typically used in transfer applications.

• Extrusion

Extrusion involves using a piston pump to apply medium to high-viscosity materials. Typical extrusion applications require accessories such as pump lifters. Power-Piston and Dynamic-Primer pumps are commonly used in extrusion applications.

• Coating application

This involves the application of material either by spraying or dipping. Coating applications utilize Double-Ball pumps.

• Metering / dispensing

Metering and dispensing involve the delivery of a specified amount of liquid on a repetitive basis. Metering/dispensing applications use Double-ball, Power-piston, and Dynamic-primer pumps.

SAMOA's different types of piston pumps and applications

Double ball piston pumps

Double ball piston pumpsThese pumps are engineered to manage a variety of high-viscosity fluids, accommodating viscosities up to 20,000 cPs. They are capable of operating at a maximum pressure of 70 bar (1,000 psi) and can deliver flow rates up to 20 l/min (5.2 gal/min). The versatility in handling materials such as oils, coatings, paints, and chemicals makes them suitable for a broad range of industrial and commercial applications.

Applications

• Transfer

• High-pressure spraying

• Measuring and dispensing

Materials that can be handled

• Oils

• Surface coatings

• Paints

• Chemicals

Constructed from either stainless steel or carbon steel, these robust pumps offer enhanced durability and are well-suited to various operational environments.

Oil & gas piston pumps with ultra high pressure

Oil & gas piston pumps with ultra high pressureThis type combines the suction capability of a ball check valve with the ability of a chop-check check valve to handle thicker material.

Applications

• Transfer

• Extrusion

• Measure and dispense

Materials that can be handled

• •Fat

• Glue

• Ink

• Surface coatings

• Dense material

This type of pump is designed for demanding industrial applications, making them ideal for use where high pressures and handling of difficult-to-flow materials are necessary.

Piston pumps for hygienic applications

Piston pumps for hygienic applicationsSAMOA's range of sanitary piston pumps are specially designed for use in food, cosmetic and other hygiene sensitive applications. These pumps are made of 316 stainless steel and other materials that meet FDA standards, making them ideal for strict hygiene requirements.

Applications

• Extrusion of agents into highly viscous liquids

• Exact dosing and dispensing

Manageable Materials

• Food products such as pasta, sauces, and jams

• Cosmetic and pharmaceutical products such as creams and gels

• Industrial adhesives and sealants

These pumps offer high performance with easy disassembly (Quick-Knock-Down, QKD) for quick and thorough cleaning, minimizing the risk of contamination. With the capacity to handle up to 30 liters per minute and working pressure up to 60 bar, they combine robustness with efficiency to meet the demanding needs of the aforementioned sectors.

Extrusion pumps

Extrusion pumpsExtrusion pumps offer an optimal solution for handling highly viscous liquids, up to 1,000,000 cPs. With a maximum fluid pressure of 350 bar (5,000 psi), these pumps excel in extrusion and transfer applications.

The vane inlet design enables pumping of highly viscous, sticky or stringy materials by extending the vane primary rod directly into the material. Usually equipped with a Power Ram attachment, they can deliver inks, adhesives and sealants at desired pressures and flow rates.

This pump is a perfect choice for efficient transfer and dosing of even the heaviest materials.

Area of use

Ideal for applications that require handling of very high viscosity materials. They are particularly useful in industrial processes where materials such as adhesives, sealants and thick inks must be transferred or sprayed under high pressure.

Material

The pumps are made of robust materials that are suitable for demanding industrial environments.

Design

The vane intake piston pumps have a unique design where a vane primary rod extends directly into the high viscosity material to enable efficient pumping. They also include a Power Ram attachment to facilitate material handling at desired pressures and flow rates.

Flow rate

Information on specific flow rates was not available from the sources reviewed.

Adaptability

The pumps are designed to be flexible and adaptable to different industrial needs, including the ability to handle different types of viscous materials.